It took some time after receiving my review copy before I could start a build. I read the introduction of LEGO Heavy Weapons as well as the intros to each of the four builds. Streat presents instructions for building replicas of the Desert Eagle pistol, AKS-74U assault rifle, Lee Enfield "Jungle Carbine", and a pump action SPAS combat shotgun. The Desert Eagle has an operational slide that moves back and forth when the trigger is pulled, a removable magazine, and a working safety. Due to the size of the pistol (based on the real life pistol), there isn't room in the barrel to implement a firing mechanism or rail/ramp for a LEGO bullet to slide through. The other three gun designs do shoot however. The AKS-74U features a folding stock that can lock folded as well as fully opened, uses a bolt action to fire, and has a removable magazine that can feed 13 LEGO blocks into the rifle before needing to be reloaded. The Jungle Carbine is primed by pulling a charging handle back and also features a removable magazine. Finally, the SPAS shotgun loads from an internal magazine by racking the fore grip back (the folding stock is cosmetic on this design due to the force required when pulling the grip and rubber bands back).

Related Articles

Author Jack Streat also provided a video demonstrating the operation of each of the replica weapons in his book:

After watching the video and reading part of the book, I decided that I would attempt to build the AKS-74U. The decision was mainly due to the folding stock and removable magazine.

The first thing that I had to do was acquire all the LEGO pieces. This particular design had 792 total pieces (107 different pieces) and some weren't easy to find. I used an online service called BrickLink which connects LEGO buyers with LEGO sellers around the world. The prices for individual pieces can be much more reasonable than purchasing from lego.com and many of the parts aren't even available for order from lego.com. With 107 different pieces, I didn't want to enter them in manually, so I put off the project for a couple weeks with the plan to find a few free hours to type into a spreadsheet the list of parts and number needed and to write a script to convert it into an XML format for input into BrickLink's wanted lists. Luckily, I procrastinated long enough that Jack Streat provided BrickLink XML files available from No Starch Press (mirrored on CFE). He provided a couple versions for each design which, after importing, would designate the desire for new parts, used parts, and wether or not BrickLink should notify the user when a seller has an item in stock. I imported with the new (no notify) list into my BrickLink wanted page by just copy-and-pasting the contents of the XML file into the XML text form on BrickLink's page. In truth, it wasn't so simple - BrickLink just happened to be down for a couple weeks due to security issues and had to initiate a database rollback. Many of the pages, including the wanted list, weren't operational when I got my hands on the XML file, so I had to wait a few more days. Then, I did the cut and paste, and it all worked... but I had to wait another day for me to be able to search the sellers.

I found the seller that had the most items that I needed and placed an order for all of those and then removed them from my wish list. I then looked for the seller who had the most items from my remaining wish list and bought as much as I could from them. The first two sellers each had around 35 different items (out of the 107 different items I needed). In the end, I placed orders with 11 different LEGO sellers (9 in the United States and 2 in Europe) in order to source all my parts. I bought as many new parts as I could, but ended up having to purchase about a dozen used. I spent roughly $110 including taxes and shipping and probably could have shaved $20-30 off that cost (or even more) by buying more used parts and/or spending more time finding vendors selling pieces at lower cost. (I went with the fastest way to order instead of trying to minimize cost.) Once I received all the parts (and left positive reviews for the sellers), I (with Tina's help) sorted all my parts into bins for easy access (marking my bill of materials with which bin, row, and column each different part was in to help me look them up during the build).

I found the seller that had the most items that I needed and placed an order for all of those and then removed them from my wish list. I then looked for the seller who had the most items from my remaining wish list and bought as much as I could from them. The first two sellers each had around 35 different items (out of the 107 different items I needed). In the end, I placed orders with 11 different LEGO sellers (9 in the United States and 2 in Europe) in order to source all my parts. I bought as many new parts as I could, but ended up having to purchase about a dozen used. I spent roughly $110 including taxes and shipping and probably could have shaved $20-30 off that cost (or even more) by buying more used parts and/or spending more time finding vendors selling pieces at lower cost. (I went with the fastest way to order instead of trying to minimize cost.) Once I received all the parts (and left positive reviews for the sellers), I (with Tina's help) sorted all my parts into bins for easy access (marking my bill of materials with which bin, row, and column each different part was in to help me look them up during the build).At this point, I discovered one of the LEGO vendors had sent a single incorrect part. It was similar to the part I needed, but not the right one and the part I received wouldn't work. I immediately put in an order with a twelfth LEGO seller for the missing component and started my build in hopes that I wouldn't hit a dead end too early with that missing part.

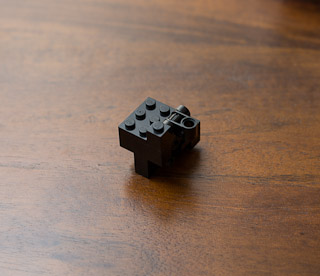

As I mentioned earlier, each of the guns is designed and built in modules. This made the instructions pretty easy to follow and also provided good stopping points for taking a break and returning later. Here is the Stock Lower Front.

As I mentioned earlier, each of the guns is designed and built in modules. This made the instructions pretty easy to follow and also provided good stopping points for taking a break and returning later. Here is the Stock Lower Front. The Stock Lower is built from the Stock Lower Front.

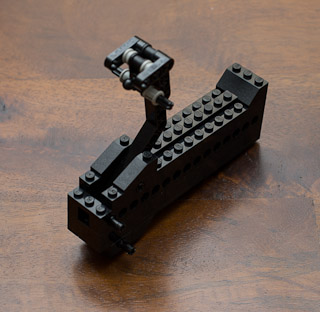

The Stock Lower is built from the Stock Lower Front. The Stock Butt

The Stock Butt The Stock Upper Plate

The Stock Upper Plate The Stock Lower, Lower Plate (not shown previously), Butt, and Upper Plate join together to form the Stock.

The Stock Lower, Lower Plate (not shown previously), Butt, and Upper Plate join together to form the Stock. The Frame Wall Left is built onto the completed Stock and, at this point, it is clear how the pivot mechanism will operate allowing the stock to fold to the side. About an hour of build time was used to get to this point. In the end, I would take about four hours to build the AKS-74U.

The Frame Wall Left is built onto the completed Stock and, at this point, it is clear how the pivot mechanism will operate allowing the stock to fold to the side. About an hour of build time was used to get to this point. In the end, I would take about four hours to build the AKS-74U. Trigger

Trigger Pistol Grip Underside

Pistol Grip Underside The Pistol Grip Underside is then built onto to form the Pistol Grip Assembly.

The Pistol Grip Underside is then built onto to form the Pistol Grip Assembly. Here you can see (from left to right) the Internals Magazine Ramp, Pistol Grip Assembly, Magazine Release, Internals Lower, Internals Walls, and Trigger. It was at this point that I needed that missing piece. I sent a text message to my friend Jack (who writes Eating in a Box and is an avid LEGO builder as well as my archery partner) to see if he had the piece (sending LEGO part number and description) and then went to bed. The next morning, I went to archery practice and afterward Jack handed me the piece that I needed!

Here you can see (from left to right) the Internals Magazine Ramp, Pistol Grip Assembly, Magazine Release, Internals Lower, Internals Walls, and Trigger. It was at this point that I needed that missing piece. I sent a text message to my friend Jack (who writes Eating in a Box and is an avid LEGO builder as well as my archery partner) to see if he had the piece (sending LEGO part number and description) and then went to bed. The next morning, I went to archery practice and afterward Jack handed me the piece that I needed! The next modules to be built were the Internals Upper, Internals Fore Sight, Internals Hammer, and Internals Bolt.

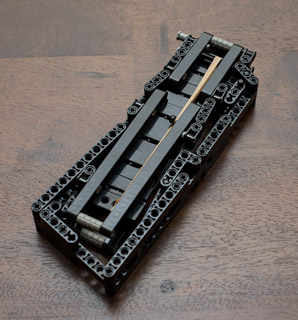

The next modules to be built were the Internals Upper, Internals Fore Sight, Internals Hammer, and Internals Bolt. All the internals fit together so the bolt will slide the hammer back where the hammer will be locked into place behind the trigger.

All the internals fit together so the bolt will slide the hammer back where the hammer will be locked into place behind the trigger. Here are the internals assembled together with the bolt hanging out (the bolt won't stay in place until more of the frame is constructed).

Here are the internals assembled together with the bolt hanging out (the bolt won't stay in place until more of the frame is constructed). The Frame Wall Right has a rubber band that is used to provide tension on the piece that pivots to release the folding stock from its unfolded (out) position. I ended up double looping this rubber band to provide a significant amount of force keeping the lock in place. To release the stock from unfolded position, I just push on the locking piece and the high tension rubber band provides just the right amount of resistance so I know the stock won't accidentally come unlocked unless I intend it to. It also isn't so tight that when unfolding the stock it won't pivot into position to lock the stock in place.

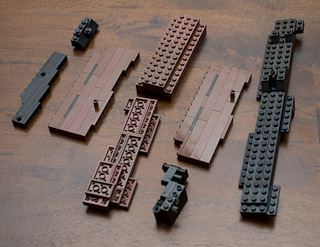

The Frame Wall Right has a rubber band that is used to provide tension on the piece that pivots to release the folding stock from its unfolded (out) position. I ended up double looping this rubber band to provide a significant amount of force keeping the lock in place. To release the stock from unfolded position, I just push on the locking piece and the high tension rubber band provides just the right amount of resistance so I know the stock won't accidentally come unlocked unless I intend it to. It also isn't so tight that when unfolding the stock it won't pivot into position to lock the stock in place. I built the Fore Grip Walls with brown LEGO pieces instead of red to mimic the wood used in many AK-74s.

I built the Fore Grip Walls with brown LEGO pieces instead of red to mimic the wood used in many AK-74s. The magazine uses a rubber band looped around a pivot to provide a spring force to keep 1x4 LEGO "bullets" ready to feed into the gun. The key is to stack the LEGO bullets so they face in opposite directions (button to button, hole to hole) so they don't interlock while in the magazine.

The magazine uses a rubber band looped around a pivot to provide a spring force to keep 1x4 LEGO "bullets" ready to feed into the gun. The key is to stack the LEGO bullets so they face in opposite directions (button to button, hole to hole) so they don't interlock while in the magazine. Here is the fully completed rifle with magazine... and, yes, it really does shoot.

Here is the fully completed rifle with magazine... and, yes, it really does shoot.It did "explode" on me after pulling the bolt back and pulling the trigger due to two mistakes I made during the build. After correcting those problems, the gun would fire, but I had issues with the magazine failing because the LEGO piece that holds the "bullets" in place (a piece that prevents them from being pushed out by the rubber band) couldn't withstand the force of either the bolt being pulled back (which is substantial) or the shock of the hammer flying forward (most of the length of the barrel) after trigger release. This is a known problem with the magazine design and Streat provides a couple alternatives to preventing that piece from failing. (If you're lucky, the piece will have enough friction to be held in place and you won't have to implement any of the workarounds.) At the time of this writing, two pieces needed for the workaround I've selected are in the process of getting ordered, so I don't know how well the workaround works.

All in all, I found the build to be quite pleasant and the instructions easy to follow with only a few difficulties caused by the grayscale printing. The explanation of how Streat came up with the designs and used real measurements and photographs to try to keep the look of the weapons he was replicating was fascinating (as were the photos of early prototypes). As someone who hadn't picked up a LEGO set for several years, this was a very interesting and satisfying way to get back into a very cool and mentally stimulating hobby.

If you purchase LEGO Heavy Weapons at Amazon.com through one of these links, a portion of the sale will go to helping maintain Cooking For Engineers.

Related Articles

About 4 hours.